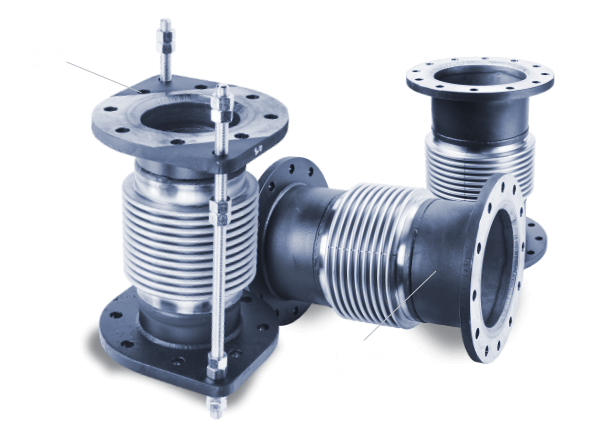

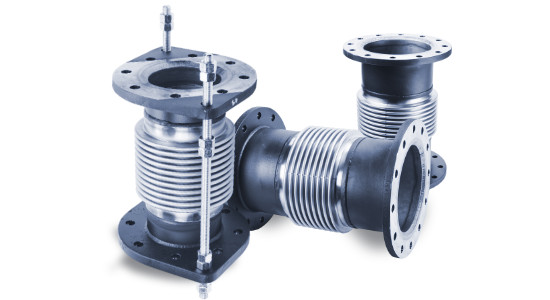

LONGER METAL BELLOWS FOR MORE AXIAL MOVEMENT

Fully configurable: materials, end style, hardware

24hr Shipping

On all stock items ordered.

Mon-Thur by 12:30pm, 9:30am Fridays

Design & Manufacturing

Full in-house design & manufacture to EN / ASME / PED.

ISO14001 Accreditation

FlexEJ has an accredited Environmental Management System.

Long Axial Industrial Metal Bellows

Fully configurable, high quality industrial metal bellows designed for long axial movements:

PRODUCT GUIDES

INDUSTRIAL METAL BELLOWS

WHAT ARE LONG-AXIAL INDUSTRIAL METAL BELLOWS?

LONGER BELLOWS PROVIDE GREATER MOVEMENT..

Design

Extensive range of configurable metal bellows suitable for a wide range of industrial services.

Application

FlexEJ will help you select the right bellows for the application.

Configurable

30-40mm of axial movement and length variation depending on diameter, flanges, weld ends, materials can all be specified to order.

Rating

16 Barg @ 180°C to 12 Barg @ 300°C.

LONG AXIAL INDUSTRIAL METAL BELLOWS

| SIZE | LENGTH | PRESSURE RATING | MOVEMENT | IN SHOP |

|---|---|---|---|---|

| DN100-4″ | 210 to 450 | 16 Barg @ 180 ºC to 12 Barg @ 300 ºC | Axial +/-30 mm | |

| DN125-5″ | 210 to 480 | 16 Barg @ 180 ºC to 12 Barg @ 300 ºC | Axial +/-35 mm | |

| DN150-6″ | 250 to 500 | 16 Barg @ 180 ºC to 12 Barg @ 300 ºC | Axial +/-35 mm | |

| DN200-8″ | 250 to 550 | 16 Barg @ 180 ºC to 12 Barg @ 300 ºC | Axial +/-35 mm | |

| DN250-10″ | 250 to 600 | 16 Barg @ 180 ºC to 12 Barg @ 300 ºC | Axial +/-35 mm | |

| DN300-12″ | 280 to 600 | 16 Barg @ 180 ºC to 12 Barg @ 300 ºC | Axial +/-40 mm | |

| DN350-14″ | 280 to 600 | 16 Barg @ 180 ºC to 12 Barg @ 300 ºC | Axial +/-40 mm | |

| DN400-16″ | 300 to 600 | 16 Barg @ 180 ºC to 12 Barg @ 300 ºC | Axial +/-40 mm |

How to specify a metal expansion joint

We design and manufacture metal expansion joints so you are not restricted to our range of standard products, some of which are available in our web shop. For simpler applications a standard product may be entirely suitable but if not we will design to meet your exact requirements.

We design and manufacture metal expansion joints so you are not restricted to our range of standard products, some of which are available in our web shop. For simpler applications a standard product may be entirely suitable but if not we will design to meet your exact requirements. Metal bellows have a defined fatigue life based on movement cycles. Understanding the movements, if they are concurrent or not and the realistic number of times the movements can occur is fundamental to metal bellows design.

Metal bellows have a defined fatigue life based on movement cycles. Understanding the movements, if they are concurrent or not and the realistic number of times the movements can occur is fundamental to metal bellows design. Metal bellows work well up to around 500ºC, above that we use insulation to control the actual bellows metal temperature if the media is above this temperature. Pressure and temperature must be known to select a metal expansion joint.

Metal bellows work well up to around 500ºC, above that we use insulation to control the actual bellows metal temperature if the media is above this temperature. Pressure and temperature must be known to select a metal expansion joint. The most common material used for metal bellows is Stainless Steel – 304, 321, 316 – and for more demanding applications Nickel Alloys – 625, 800, 825. Corrosion is the most likely failure mode for the bellows itself so the correct material selection is important.

The most common material used for metal bellows is Stainless Steel – 304, 321, 316 – and for more demanding applications Nickel Alloys – 625, 800, 825. Corrosion is the most likely failure mode for the bellows itself so the correct material selection is important. Our standard ranges have set lengths for each diameter / movement range but we can design to meet your exact requirements. Making the bellows longer will increase the available movement. Most commonly a flange, we can provide to any specification, or pipe weld ends. Our HVAC standard product is available with BSP Union ends and Copper Pipe ends. If you are uncertain about what flange type you already have installed our Flange Finder will help you identify it.

Our standard ranges have set lengths for each diameter / movement range but we can design to meet your exact requirements. Making the bellows longer will increase the available movement. Most commonly a flange, we can provide to any specification, or pipe weld ends. Our HVAC standard product is available with BSP Union ends and Copper Pipe ends. If you are uncertain about what flange type you already have installed our Flange Finder will help you identify it. Call our expert team on +44 (0) 1384 881188 or email us at sales@flexej.co.uk or use Live Chat on this web site – we are here to help, please get in touch.

Call our expert team on +44 (0) 1384 881188 or email us at sales@flexej.co.uk or use Live Chat on this web site – we are here to help, please get in touch.FlexEJ's Industrial Long Axial Metal Bellows

FlexEJ’s Industrial Long Axial Metal Bellows for hot gases, steam, exhaust and other industrial process applications:

| Length to order | Flange type and material to order |

| Weld end type and material to order | Stainless steel liner |

| EJMA designed punch formed bellows | DN100-DN400 |

Specifications

Can't see what you want? Need help?

Call us. Or use Live Chat.

For instant advice. We can custom-design and engineer almost any expansion joint you need for delivery in the UK or worldwide. Call our expert team on +44 (0) 1384 881188 Or email us sales@flexej.co.uk

HVAC & Industrial Bellows Comparison Charts

What is the best kind of pump or axial bellow for your application? Four potential alternatives to consider:

Stainless steel  Bellows Material and Design

Bellows Material and Design

Is the bellows Stainless Steel and calculated to EJMA?

Flow Liner  Flow Liner

Flow Liner

Is a Flow Liner included?

Any flange / weld end  Any Flange or Weld End

Any Flange or Weld End

Is any common flange type or pipe weld end available?

Range of length  Range of lengths

Range of lengths

Can an overall length greater than minimum be specified?

Rating barg/°C

Can't see what you want? Need help?

Call us. Or use Live Chat.

For instant advice. We can custom-design and engineer almost any expansion joint you need for delivery in the UK or worldwide. Call our expert team on +44 (0) 1384 881188 Or email us sales@flexej.co.uk

Frequently Asked Questions

A. Our Flange Finder contains details for many common flanges. Typically, to be able to make the identification you need to know the bore size or outside diameter and number of bolts. For technical assistance contact us or use our Live Chat facility.

A. Yes, FlexEJ has full design capability for engineered metal expansion joints and can work to any recognised standard – typically EJMA, B31.3/Appendix X, EN14917 plus PED and/or other customer specifications. Engineered rubber expansion joints are typically designed to meet the FSA guidelines plus PED and/or other customer specifications For technical assistance please contact us or use the Live Help link on this page.

A. Yes, if you have the details we can normally offer an equivalent, our FAQ here gives the information we will need for a full selection. For technical assistance please contact us or use the Live Chat link on this page.

A. To identify an existing expansion joint we need to know: nominal bore, overall length and flange type plus service, temperature, pressure and required movement if known. Try our Flange Finder to help identify the flange and you can send us a picture of the existing part using the Contact us form. For technical assistance please contact us or use the LIVE CHAT link on this page.

A. Yes, our MRCA copper ended metal expansion joints also have WRAS approval. We laso have DWI approval for stainless steel expansion joints. For technical assistance please contact us or use the Live Chat link on this page.